All Articles

Electrospinning: A Versatile Approach of Making Nanomaterials

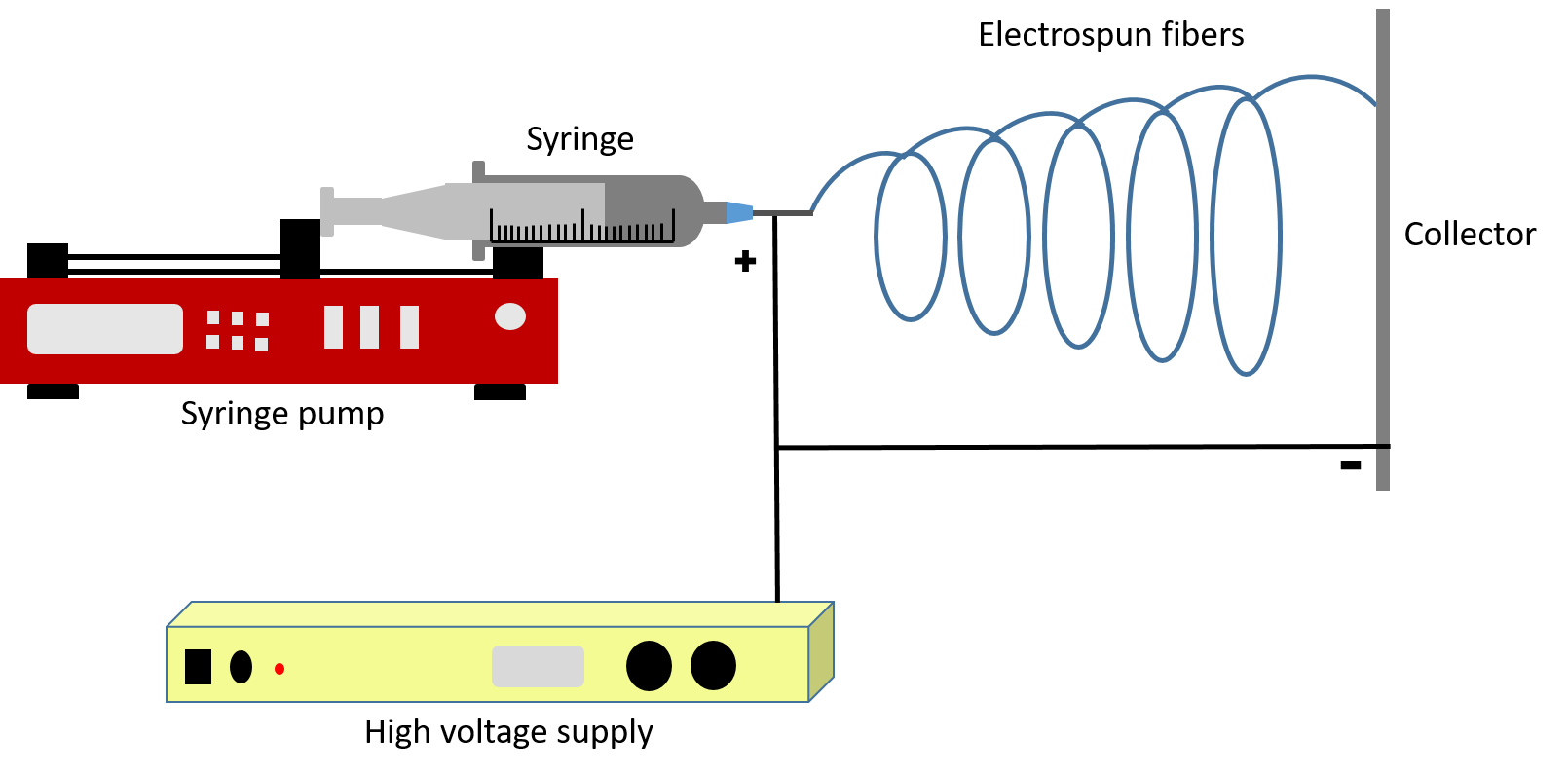

Electrospinning is a method extensively used for producing nanomaterials, particularly nanofibers. It is a technique where, a high voltage electric field is used to produce electrically charged jets from a polymer solution which then upon evaporation make nanofibers of the polymer. Generally, any electrospinning apparatus consists of three major components namely, a high voltage supply, a spinneret (metallic needle) and a collector (Figure 1). Usually the polymer solutions are fed using a syringe pump at a controlled rate. The highly charged fibers are field directed towards the oppositely charged collector, which can be a flat surface or a rotating drum, to collect the fibers. In conventional spinning techniques, the fiber is subjected to a group of forces such as tensile, gravitational, aerodynamic, rheological, and inertial, whereas in electrospinning, the spinning of fibers is achieved primarily by the tensile forces created in the axial direction of the flow of the polymer by the induced charges in the presence of an electric field.

Figure 1. Schematic diagram of electrospinning apparatus

Further, by modifying simple electrospinning, a further step has moved forward to make coaxial electrospinning, in which by introducing multiple feed solutions to simultaneously electrospin two or more polymer solutions from coaxial capillaries. The spinnerets are sharing an axis, allowing for the injection of one solution into the other at the needle tip with the core fluid getting drawn within the outer one to produce continuous coated or hollow nanofibers.

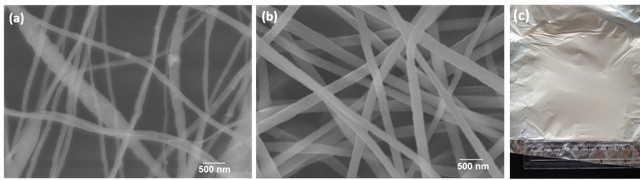

Typically, the produced nanomaterials are in fiber form in conventional electrospinning and core-shell structured fibers in coaxial electrospinning., which results in fiber mats or thin sheets. Usually the nanofibers are having very small diameters (<100 nm) are obtained by this technique. However, this simple basic 2-D mat form of electrospinning product has now advanced into making more complex structures with different shapes and even 3-D dimensions. Therefore, the applications of electrospinning varies from making water filtration membranes, advance textiles such as wearable electronics, energy devices such as battery/ supercapacitor electrodes and sensors, to biomedical applications such as wound dressings, drug delivery, tissue implants, biological scaffolds and also as a nanoencapsulation method to deliver drugs, cosmetics, fertilizers, etc. The versatility of electrospinning method lies in the fact that y modifying the polymer solutions with the materials as per the application and also the fibers can be modified in terms of constituents in order to improve properties like mechanical properties, which are crucial in practical applications of using such materials. For example, an electrospun wound dressing can be prepared by adding antimicrobial agents to the neat polymer solution and also by including clay-like material to improve its tensile strength and hardness.

Figure 2. (a) and (b) Scanning electron microscopic images of electrospun fibers at different magnifications (c) An electrospun nanofiber mat

References

- Li, D., Xia, Y., Mater. 2004, 16 (14), 1151-1170.

- Subbiah, T., Bhat, G. S., Tock, R. W., Parameswaran, S., Ramkumar, S. S., Appl. Polym. Sci. 2005, 96 (2), 557-569

- Ramakrishna, S., Fujihara, K., Teo, W.-E., Yong, T., Ma, Z., Ramaseshan, R., Today. 2006, 9 (3), 40-50.

Dr. Induni W. Siriwardane

B.Sc. (Chemistry) Hons (Colombo), M.Sc. (Iowa, USA), MBA (PIM), PhD. (Colombo)

Director – Center for Advanced Materials and Smart Manufacturing (CAMSM)

Senior Lecturer – Department of Applied Computing

Faculty of Computing and Technology

University of Kelaniya