All Articles

Introduction to 3D Printing Technology

3D Printing, also referred to as Additive Manufacturing (AM), is a technology that manufactures a three-dimensional solid object in layer-by-layer fashion from a computer aided design (CAD) model. Being three-dimensional, these objects have a certain length, width, and thickness. AM has the capability of manufacturing simple to complex geometries as long as the desired shape is available as a CAD-based .stl file. The ability of AM to produce complex geometries that are not conducive with conventional techniques such as injection moulding, blow moulding, extrusion, or other transfer moulding methods, make AM unique among the material fabrication technologies. The AM technology is capable of processing a myriad of materials including thermoplastic polymers, composites, hydrogels, semi-solids, concrete, ceramics, metals and alloys etc. Due to the wider processability of materials, AM finds different printing techniques each having its own mechanism of printing the material. These techniques consist of extrusion, vat-photopolymerization (VP), jetting, powder bed fusion (PBF), directed energy deposition (DED), and laminated object manufacturing (LOM). Due to the unique ability of producing complex structures, wider processability of materials, and existence of different techniques, AM finds a potential emerging $1 trillion market by 2030 for improved 3D printed parts (Davidson et al. 2016).

Following section summaries the most frequently used 3D printing techniques.

Extrusion

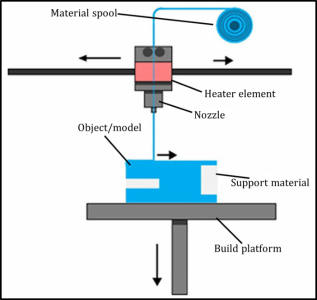

There are two extrusion based 3D printing techniques, fused filament fabrication (FFF) and direct ink writing (DIW). In FFF, a thermoplastic filament is fed through the machine and heated at the print head (Figure 1). Material melts and get extruded through a nozzle on to a print bed as a layer. The shape of the layer is determined by the movement of the nozzle which is in accordance with the computer aided design (CAD) file of the object to be 3D printed. After completing the first layer, the process continues building up the object layer-by-layer fashion (Appuhamillage et al. 2018). Layers are cooled at ambient conditions making a solid 3D printed object on the print bed. FFF is versatile to 3D print various thermoplastic polymers and composites for applications such as household appliances, toys, and other prototypes.

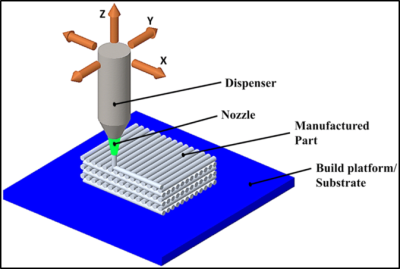

In the DIW technique (Figure 2), a semi-solid/hydrogel/concrete type shear-thinning material is loaded onto a syringe, pressurized, and extruded through a needle like nozzle on to a print bed layer-by-layer (Appuhamillage et al. 2019). Again, the shape of the layers are governed by the CAD file of the object to be 3D printed. Usually, the printed material is then immediately cured under UV light to provide an additional strength. DIW finds applications mainly in biomedical and construction fields.

Figure 1. Schematic Diagram of the FFF 3D Printing Process.

Adapted from: Rivera et al. Int. J. Adv. Manuf. Technol. 2020

Figure 2. Schematic Diagram of the DIW 3D Printing Process.

Adapted from: Khan et al. Prog. Addit. Manuf. 2020

Vat Photopolymerization (VP)

In VP, a photo-curable resin is loaded into a vat, and a UV laser rasters the required pattern (shape) on the resin surface, thereby cross-linking the liquid resin into a solid. Upon recoating a fresh layer of the photo-resin and patterning with the UV laser, subsequent solid layers will be formed building up the 3D object (Appuhamillage et al. 2019). There are several VP-based AM techniques. These basic techniques include stereolithography (SLA), digital light projection (DLP), two-photon lithography, and digital light synthesis (DLS). Out of these, 4D printing has been carried out mainly via SLA and DLP. Many organic-based photo-polymers are 3D printed for applications including biomedical and dental sectors.

Powder bed Fusion (PBF)

Powder bed fusion (PBF) is another very versatile additive manufacturing technique that can 3D print metals, ceramics, glass, and various types of polymers that are in powder form. PBF use either a laser or electron beam to melt and fuse material powder together. PBF processes include direct metal laser sintering (DMLS), electron beam melting (EBM), selective heat sintering (SHS), selective laser sintering (SLS), and selective laser melting (SLM). In a typical PBF AM process, an initial layer of material powder is spread over the build platform. This first layer (first cross section) is then fused by heat generated by a laser or high energy electron beam. A new layer of powder is then spread across the previous layer using a roller or a blade, fused and the process continues until the entire model is created. Unfused powder is removed during post-processing.

References

- Davidson, J. R.; Appuhamillage, G. A.; Thompson, C. M.; Voit, and Smaldone, R. A. ACS Appl. Mater. Interfaces, 2016, 8, 16961-16966.

- Appuhamillage G. A.; New 3D Printable Polymeric Materials for Fused Filament Fabrication (FFF), The University of Texas at Dallas, 2018.

- Appuhamillage, G. A.; Chartrain, N.; Meenakshisundaram, V.; Feller, K. D.; Williams, C. B.; Long, T. E. 110th Anniversary: Vat Photopolymerization-Based Additive Manufacturing: Current Trends and Future Directions in Materials Design. Eng. Chem. Res. 2019, 58 (33), 15109–15118.

- Mercado Rivera, F. J.; Rojas Arciniegas, A. J. Additive Manufacturing Methods: Techniques, Materials, and Closed-Loop Control Applications. Int. J. Adv. Manuf. Technol. 2020, 109 (1), 17 31.

- Khan, S.A., Lazoglu, I. Development of additively manufacturable and electrically conductive graphite–polymer composites. Prog Addit Manuf5, 2020, 153–162.

- Appuhamillage G.A.; Berry D.R.; Benjamin C.E.; Luzuriaga M.A.; Reagan J.C.; Gassensmith J.J. et al. A biopolymerbased3D printable hydrogel for toxicmetal adsorption from water. Polym Int.2019; 68: 964–71.

Dr. A.A. Gayan Kavinda Siriwardana

B.Sc.(Hons)(UOK-SL), M.Sc.(USA), Ph.D.(USA), Post-Doctoral Fellow(USA)

Senior Lecturer,

Department of Materials and Mechanical Technology,

Faculty of Technology,

University of Sri Jayewardenepura.